HF Systems

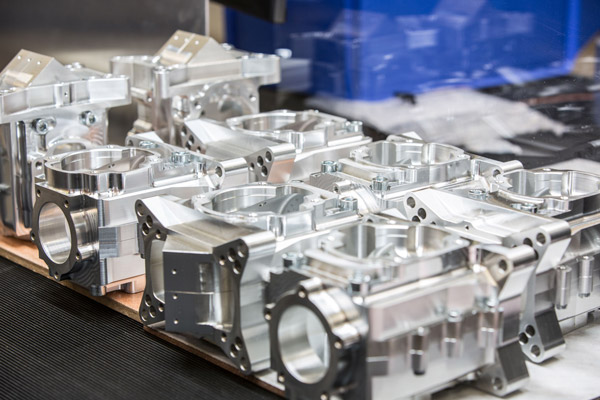

Due to the fact that existing engines in the market did not fulfil the high standard of Sky Power International, management decided to start their own project for a heavy fuel solution. In 2007, the first heavy fuel UAS-engines were designed. Several developments were made and tested until the R&D department decided on the final engine design.

After the first prototypes had been produced, the engines were tested under various severe conditions. At the test-facility, the engines had to run without difficulties.

The combination of these modifications and the new development constituted the breakthrough in heavy fuel technology. The engines proved their outstanding reliability during the extensive test runs.

- The programme for the break-in procedure can be modified to meet the end user’s specifications.

- For UAS-engines with less 3.30 cu in cylinder capacities, manually operated compression release valves as an option can be used for an easy start of the engine.

- For UAS-engines with a cylinder capacity of 20,68 cu in and more, manually operated compression release valves are available as an option. This will reduce the load of the crankshaft if an external heavy-duty electrical starter is used. In addition, the engine can be easily stopped and restarted while the craft is in the air. This requires an on-board starter or an alternator/starter unit.

- The engine mounting plate is designed for mounting an additional 4th ball bearing to support the rear output shaft. Only the mounting plate needs to be redesigned if an alternator or starter unit is used. Generator mounting plates for various generator suppliers are available.

- The rear output shaft is a standard feature and allows mounting of alternators, electric starters, and starter/alternator units. This standard is not applicable for rear induction engines.

- The Sky Power mufflers are recommended to have the most efficient engine performance. Customer solutions can be provided too.

- 3D models are available upon request.

Twin Spark

All UAS-engines beginning at 55 ccm cylinder displacement will be delivered as a twin-spark (TS) version. Both ignitions work independently of one another here.

The following benefits can be achieved using the TS version:

- The engine runs at a lower idle; general operational behaviour is quieter.

- Safety and reliability increase in both single- and multiple-cylinder engines when using the TS cylinder.

- When one ignition fails, the second ignition working independently ensures that the engine continues to run with slightly reduced RPM.